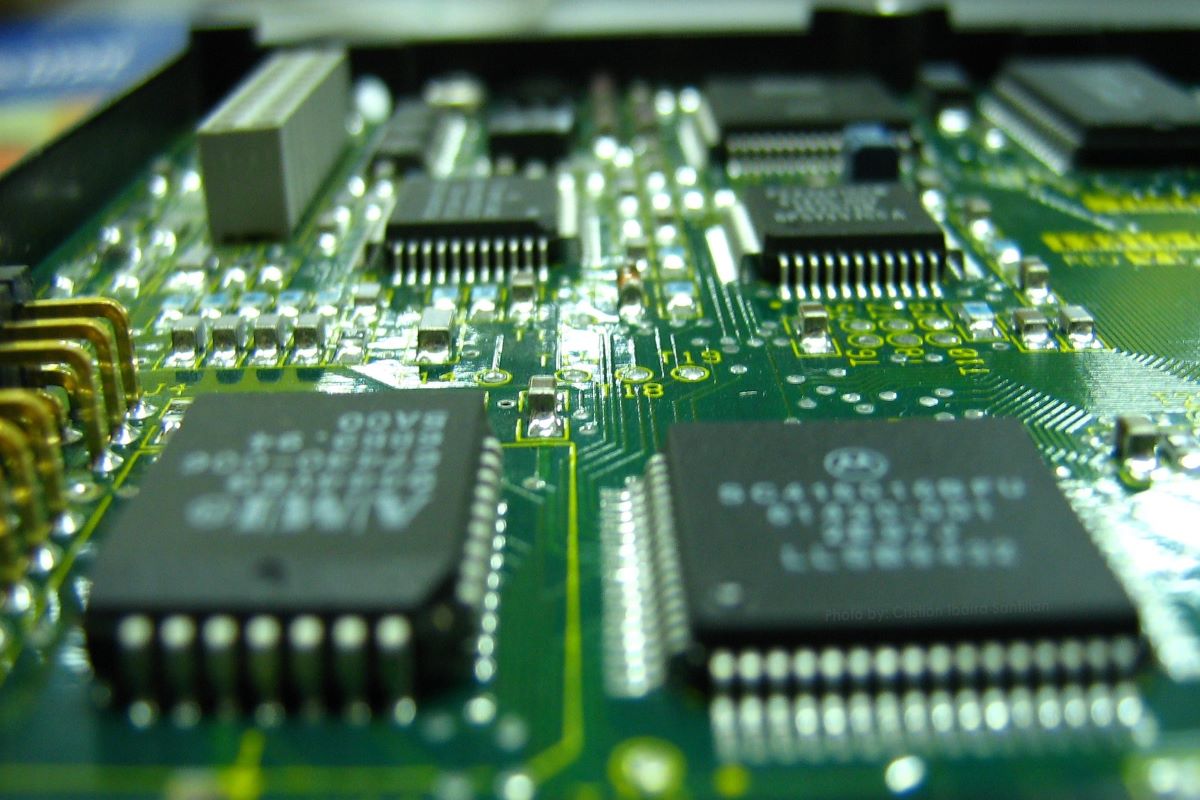

Amid the ensuing China-US chip war, China chip companies, along with state-backed funds, plan to invest around 50 bn yuan ($7.26 bn ) to bolster the country’s semiconductor supply chain, as per local media outlets.

The Chinese government, as part of its ‘Made in China 2025’ strategy, had previously granted subsidies to Chinese enterprises that produce chip manufacturing equipment. As a result, the country’s semiconductor factories boosted the use of domestic equipment by 31% in 2022, up from 21% in 2021. Additionally, domestic companies have secured roughly half of all public bids for equipment by key Chinese chip makers in 2023.

According to a local Chinese media outlet, the government has granted 12.1 bn yuan ($1.75 bn) in subsidies to 190 domestically listed semiconductor businesses in 2022. The ten biggest beneficiaries received 45% of the total proceeds, totaling 5.46 bn yuan ($789.2m).

China’s largest chip foundry Semiconductor Manufacturing International Corporation was the largest beneficiary of government subsidies last year. SMIC was followed by the Chinese LED chipmaker Sanan Optoelectronics and the chip packaging firm Tianshui Huatian Technology. Wingtech Technology, Yangtze Memory Technologies, Loongson Technology, and the Naura Technology Group were among other major recipients.

“We cannot avoid decoupling in semiconductors…This will be the greatest opportunity for Chinese enterprises that make production machinery and materials,” said Chiu Tzu-Yin, president of state-backed wafer giant National Silicon Industry Group (NSIG) at a chip supply chain conference in Guangzhou.

Growth in China chip-making equipment suppliers

China’s memory chip makers, blacklisted by the US, are now turning to domestic suppliers in a bid to strengthen their supply chains. The Yangtze Memory Technologies Corp (YMTC), which accounts for 6% of the global market for 3D NAND memory chips, was added to the ‘Entity List’ by the US government late last year. This was done to restrict the company from gaining access to US products and services without prior government approval.

Subsequently, as per reports by a Chinese media outlet, the company has placed big orders with domestic chip suppliers. This includes the Naura Technology Group, which displayed a robust sales performance last year.

Naura, which is China’s leading manufacturer of chip-making devices saw its revenue increase six-fold to 14.6 bn yuan (~$2.11 bn) in 2022 from 2017, right before the recent trade war between the US and China kicked off. The company has also begun building a plant in Shanghai worth 1.5 bn yuan (~$0.22 bn).

Among other players in the sector, Advanced Micro-Fabrication Equipment, China’s second-largest manufacturer of chipmaking tools, witnessed a five-fold increase in revenue in 2022 as compared to 2017. In addition, NSIG’s revenue also increased five times between 2017 and 2022, and the company raised funding of 10 bn yuan (~$1.44bn) last year.

Overall, sales of China’s chip-making equipment materials increased six-fold between 2017 and 2022, reaching 53 bn yuan (~$7.7bn) and 62 bn yuan (~$8.97 bn), respectively. Despite a 5% reduction, China was ranked first in the world in chip-making equipment sales for the third consecutive year in 2022 and it will retain its lead position next year too, according to the global industry association SEMI.

“Despite the bleak short-term outlook, some industry experts – even in the US – warn that the latest proposed restrictions might not hold back China’s microchip technology for long. Most Chinese tech systems rely on locally made, less sophisticated microchips – products that US export controls do not cover,” writes Chi Lo, Senior Market Strategist APAC at BNP Paribas Asset Management.

“Furthermore, if China needs cutting-edge semiconductors to further its development of AI, 5G and quantum technology, it is technically capable of producing them; it only lacks the commercial capability to scale up production,” he adds.

Australia

Australia China

China India

India Indonesia

Indonesia Japan

Japan Malaysia

Malaysia Philippines

Philippines Singapore

Singapore South Korea

South Korea Taiwan

Taiwan Thailand

Thailand Vietnam

Vietnam