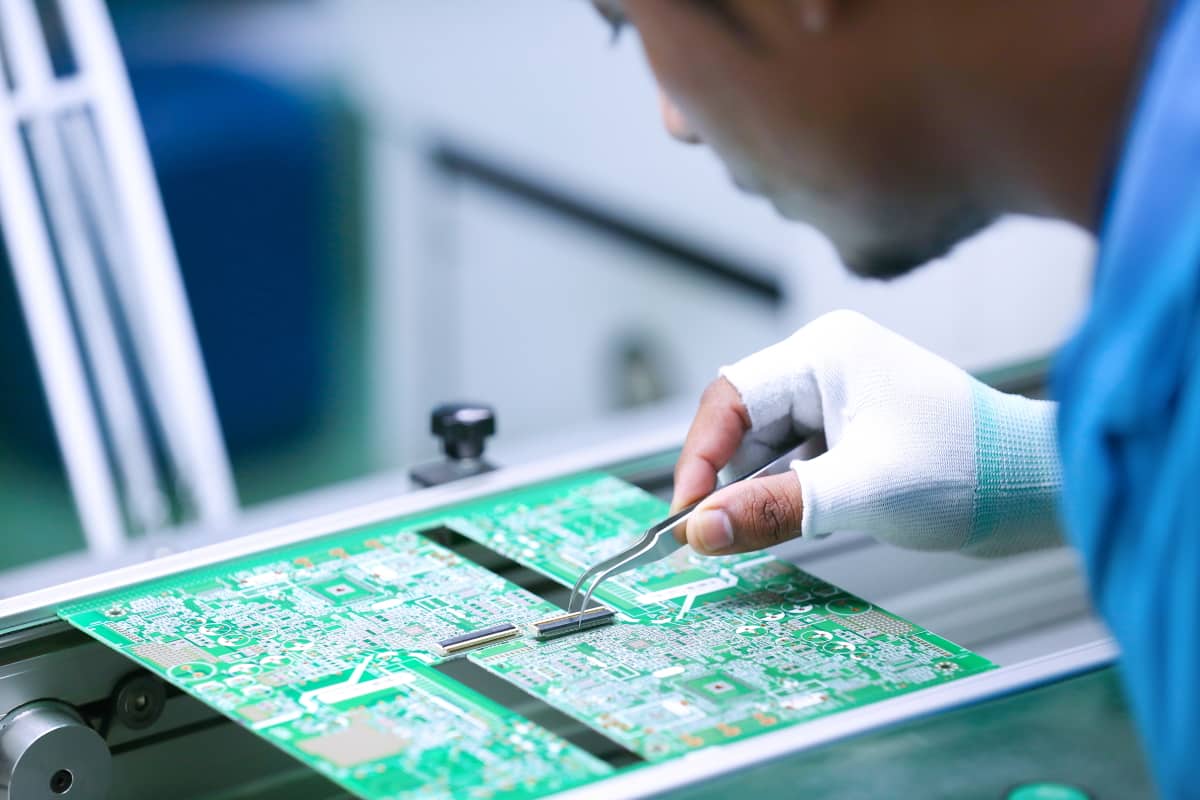

The global chip shortage has crippled the production of everything from mobile devices to cars and the situation is unlikely to improve soon even as demand rises. We previously noted the role of China and Asian Tigers (Hong Kong, Singapore, South Korea, Taiwan) in the global chip supply, now we look at the Southeast Asia semiconductor industry which is fast emerging as a solution to quell the semiconductor shortage.

In Southeast Asia, especially the ASEAN countries and India have seen a flurry of investment activity in recent years. Ernst & Young in a report said that the ASEAN’s semiconductor capability is in focus due to its diverse ecosystem of manufacturing competency. The economic bloc of 10 Southeast Asian countries is the world’s second-largest semiconductor exporter, with a 22.5% share of the global semiconductor exports in 2019. Let us look at what makes ASEAN so interesting for semiconductor firms, as well as countries like the US, Japan and South Korea.

Southeast Asia semiconductor capacity

The ongoing chip shortage has kept semiconductor supply chain stakeholders on the edge as they try to expand capacity to meet rising demand. EY says the industry needs to double capacity by 2030 to meet the rising annual demand of between 4%-5%. To understand why ASEAN could be a key to meeting this demand we need to first note that semiconductor supply chains are highly fragmented, and chips go across multiple borders before they are finally turned into the final electronics product.

EY in its report ‘When Chips Are Down’ looks into the semiconductor value chain spread across ASEAN. Malaysia, Singapore, Vietnam and Philippines and Thailand are at the forefront of research and development and IC design. Malaysia and Singapore are regional leaders in wafer fabrication, wafer production and equipment production. Malaysia, Philippines, Thailand, Vietnam and Indonesia lead in backend manufacturing, whereas Singapore and Thailand lead in engineering software.

“ASEAN is uniquely positioned as a neutral region with a well-established and diverse semiconductor ecosystem. Since the 1970s, ASEAN knows semiconductors, and its governments continue to support investments in this sector,” said Amarjeet Singh, EY ASEAN and Malaysia Tax Leader.

Additionally, five ASEAN nations are in the world’s top 15 semiconductor exporter, and the total semiconductor exports by the bloc amounted to $200 bn in 2019, as per the UN ComTrade report.

ASEAN semiconductor opportunities

ASEAN semiconductor industry has received a boost from FDI, rising exports and integration into global value chains. Singapore is the forerunner among ASEAN countries when it comes to chip production, and the city state contributed 12.4% to global semiconductor exports in 2020, as per EY. Several global chipmakers have succeeded in the country due to a conducive growth environment and government support. The country has 19% of the global market share for semiconductor equipment as of 2021.

Malaysia is the second most important country for Southeast Asia’s semiconductor industry, and six of the world’s 12 largest semiconductor firms have operations in Malaysia. The country contributed 6.3% to global semiconductor exports in 2020 and has attracted foreign investment of $35 bn in the last five decades.

“Home to leading semiconductor companies for over 50 years, Malaysia provides a cost-competitive, secure and stable location from which advanced manufacturing and R&D activities can thrive,” said Nelson Samuel, Consul Investment and Director of Malaysian Development Authority, tells EY.

The Philippines has emerged as a key electronics exporter, and in 2020 semiconductors formed 70% of its electronics exports. The country is known for its semiconductor assembly and testing facilities. The archipelago’s biggest strength is the highly skilled and service-oriented workforce.

Thailand is the world’s 13th largest exporter of electronic products and has an extensive production capacity, from semiconductors to memory devices. The kingdom is strategically located in the heart of ASEAN and the transport modes allow the country to serve as a transit hub.

Meanwhile, Indonesia is fast emerging as a semiconductor manufacturing hub after the country targeted electronics as an essential sector under Making Indonesia 4.0. It has the largest manufacturing workforce in ASEAN as well as the largest automotive market in the region, felling demand for electronic components.

Lastly, India’s (non-ASEAN country) semiconductor market was valued at $27 bn in 2021, as per the Indian Electronic and Semiconductors Association. The chip industry in the country is nascent, and ISMC Analog Fab on May 11 said it will set up a $3 bn semiconductor chip-making plant in the country.

Additionally, the electronic component exports from ASEAN are rising fast. Between 2000 to 2019, Vietnam saw the fastest growth in the region at 25.5%, followed by the Philippines (7.4%) and Malaysia (5.9%).

Why ASEAN?

DBS economist Ma Tieying in a report said the majority of foreign semiconductor firms investing in ASEAN are from the US, whereas South Korean and Taiwanese chipmakers have a larger footprint in China.

The US-China trade war has a special focus on semiconductors manufactured in China. Chipmakers are thus looking to diversify their supply chains. US, China and several other countries are vying to win the semiconductor race as demand rises.

Specifically, US and Japan plan to work with ASEAN nations to reduce reliance on China for semiconductors. Earlier this month, US and Malaysia signed a memorandum of cooperation to strengthen semiconductor supply chain resilience and promote sustainable growth.

Australia

Australia China

China India

India Indonesia

Indonesia Japan

Japan Malaysia

Malaysia Philippines

Philippines Singapore

Singapore South Korea

South Korea Taiwan

Taiwan Thailand

Thailand Vietnam

Vietnam